Transform your Predictive Maintenance Program

About VibroAI

Predictive maintenance programs require significant investment in equipment and talent. The part of the program involving vibration measurement and analysis can be particularly challenging. Vibration professionals often spend too much valuable time compiling, cleaning, and analyzing data before actionable insights can be found. VibroAI automates these tasks with its Analysis and Diagnostics platform.

VibroAI is a cloud-based platform that receives vibration data collected on industrial assets, processes it with AI, and generates actionable maintenance recommendations. The results are delivered via a user-friendly dashboard and communicated through automated email alerts when issues are detected.

The platform is fully integrated with market leading IoT sensors designed to be permanently installed on high criticality industrial assets for scheduled data collection. For less critical assets, it complements and enhances our customers’ route-based data collection services.

For existing condition monitoring platforms, VibroAI delivers machine health assessments via API integration. By leveraging this platform, companies expand their value proposition by delivering automated AI-driven predictive maintenance insights that are easy to interpret, even for non-technical personnel.

Services

VibroAI Monitoring:

Advanced Condition Monitoring Services

Efficient machine condition monitoring requires expertise in multiple technical areas, including vibration analysis and machine-specific fault patterns. Another challenge is a need to navigate through large volumes of data. With IoT technology data is collected frequently, across multiple measurement points, making manual analysis increasingly challenging.

VibroAI’s AI-assisted condition monitoring service processes every data set, constructing a virtual machine state to assess whether new measurements align with normal operation or indicate an anomaly. VibroAI automatically classifies data based on operating modes, ensuring that operational variations are not mistakenly flagged as faults.

Please review our new Electronic Brochure.

VibroAI Integrations:

Your Partner in Building Condition Monitoring Excellence

Setting up a robust condition monitoring infrastructure comes with challenges. VibroAI simplifies the process by helping you appraise asset criticality to prioritize monitoring efforts, determine the best approach, whether route-based data collection or permanent IoT sensors, and integrate the right components for seamless operation. Once your system is live, VibroAI provides ongoing technical support and personnel training, ensuring a smooth transition and measurable ROI.

Whether you're integrating with an existing platform or building from scratch, VibroAI makes implementation efficient and hassle-free. Adopting new technology can seem overwhelming, but with VibroAI, integration is seamless, strategic, and results-driven.

Products

VibroAI Analysis

VibroAI Analysis acts as a virtual vibration expert, handling complex and time-consuming tasks with ease. It automatically extracts key data features optimized for AI-driven condition monitoring. As machine speed and load fluctuate, VibroAI dynamically adjusts, ensuring precise results in every measurement cycle.

Vibration analysts gain automated detection of rotating speed and vibration levels at key frequencies, helping to identify potential mechanical faults. All calculated values are instantly available in an intuitive, user-friendly dashboard, streamlining analysis and decision-making.

VibroAI Analysis is a versatile tool that delivers value to both seasoned analysts and engineers who are new to the field.

VibroAI Diagnostics

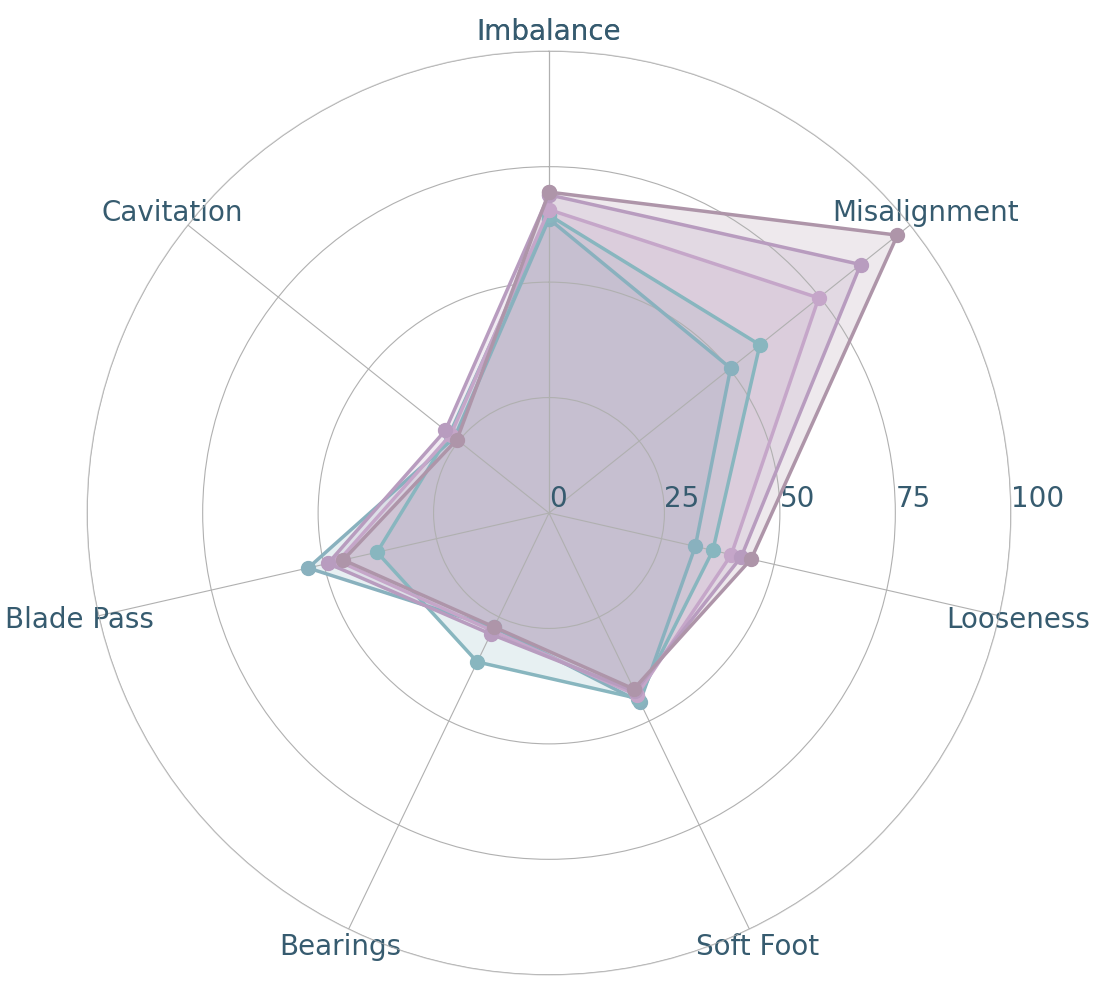

VibroAI Diagnostics transforms vibration data into actionable machine health insights. By analyzing multiple data features, the algorithms assess how closely the measured data matches machine fault patterns. It then assigns a health score from 0 to 100, where 100 indicates a confirmed issue. Users receive alerts when fault pattern scores rise, enabling proactive maintenance decisions.

Since most industrial machines operate under variable speeds and loads, vibration data naturally reflects these changing conditions. VibroAI Diagnostics differentiates between them and uses specialist input to provide a label for each condition. This Expert-in-the-Loop approach allows a knowledgeable user to supervise discovered operating modes and anomalies, refining the system’s ability to detect and classify machine faults.

Please review our new Electronic Brochure.

Contact VibroAI

Please use this form or use the contact info below to get in touch with us.

Mail:

2720 Dundee Road, Suite 105

Northbrook, IL 60062, United States

Call:

+1 847 999 3697

fax +1 847 999 0743